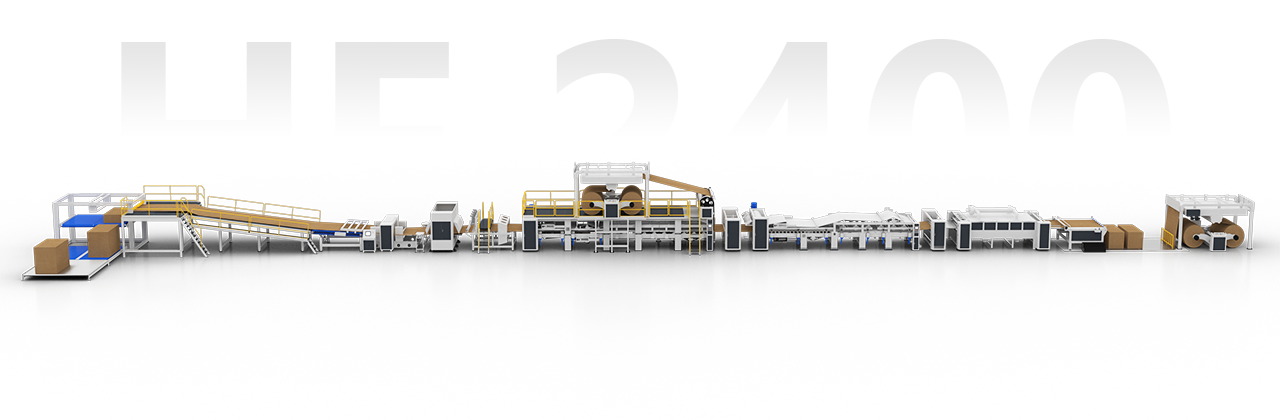

HF2400-100G

Automatic high speed honeycomb paperboard composite production line

HF2400-100G

Automatic high speed honeycomb paperboard composite production line

1. Roll the following paper (with automatic paper feeder) 2.Paper core open 3. Paper core drying 4. Glue the core paper 5.Preheat the lower paper 6. Press the lower ironing board to dry transport 7. Roll the upper paper (with automatic paper feeder) 8. Glue the core paper 9. Preheat the top paper 10. Press the upper iron plate, dry and transport 11. Cardboard cooling 12. Cardboard longitudinal cutting (line pressing) 13. Cardboard cutting 14. Cardboard conveying 15. Cardboard stacking (can be connected to the whole plant logistics)

The maximum production speed is up to 100m/ min, the whole line has a high degree of automation, low loss of base paper, and high flatness of paperboard; He has more than ten patents.

| Machine Model | HF-2400-100G |

| Core Paper Effective Width | 1500mm-2400mm |

| Thickness of end product | 4-15MM |

| Length of end product | 800MM-4500MM |

| Production speed | 100m/min |

| Heating method | Steam heating |

| Equipment power | 230KW (including cadres) |

| Overall dimensions | 82000Lx6500Wx5100H |

| Equipment weight | About 150 (including cadres) |